- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

About Us

HEC

MACHINERY

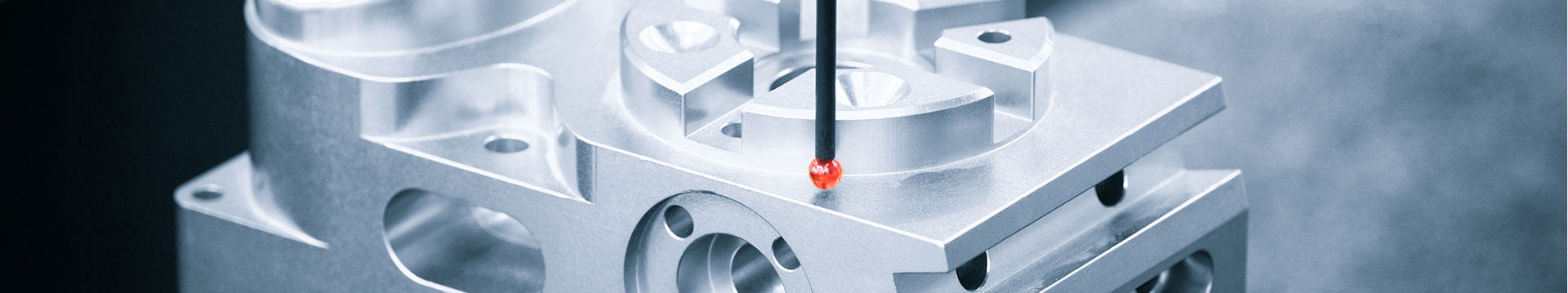

Our group covers an area of 200.000 square meters, with a production capacity of 70.000 tons annually. We have Tooling-,Casting-, Machining- and Assembly workshops, advanced production equipments and testing equipments, we have about 200 shooting machines from hot and cold core boxes, about 100 horizontal and vertical CNC, and X-ray machine, spectrum analyzers, CMM, mechanical properties testing equipments, etc. With exquisite and strong technical know-how and completed testing equipments, we provide high-quality products and first-class services for global customers, especially those in Heating, Automotive and Locomotive industries. We mainly produce aluminum castings with complex structure and many cores combinations. We can provide various casting methods such as sand casting, shell casting, gravity casting, low pressure casting and high pressure casting. Our processes include mold flow analysis, impregnation, welding, machining, assembly, heat treatment, wet & powder painting, chromate, anodizing, tumble finishing and other surface treatments. R & D and Quality Inspection include 3D, 2D software, mold flow analysis software, PPAP, CPK, CMK, 8D report, bursting test, hydrostatic test and air pressure test, etc.