- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

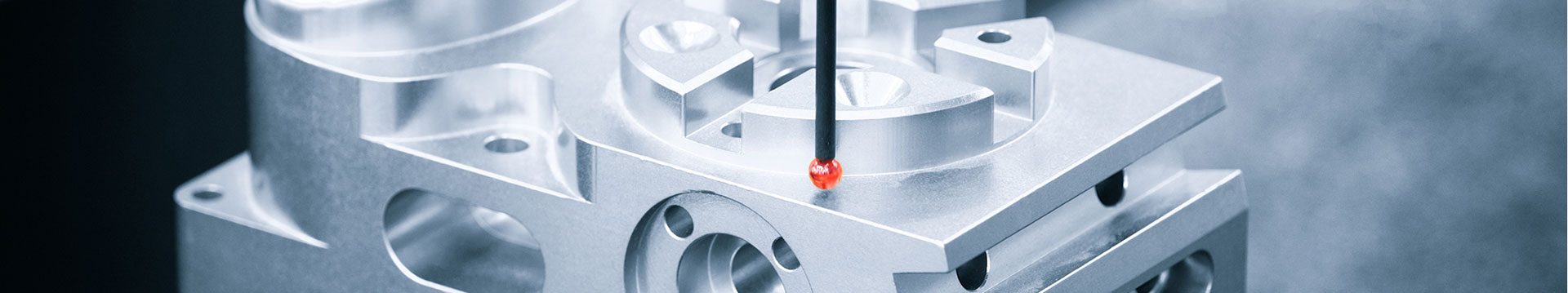

The Intricacies of Manufacturing Heat Exchanger Parts

2024-05-23

Heat Exchanger Parts are critical components in a wide range of industrial applications, from automotive to aerospace and power generation. The manufacturing process for these parts is complex, requiring precise engineering and meticulous attention to detail to ensure optimal performance and longevity.

The casting structure of Heat Exchanger Parts is notably intricate, characterized by a network of pins and water channels. This complexity presents significant challenges in the casting process. The core making stage is particularly crucial, as it involves using sand of varying mesh sizes to achieve the right balance between strength and gas permeability. This balance is essential to prevent issues such as shrinkage or core breakage during the casting process.

To address these challenges, multiple combinations of cold and hot core assemblies are used, often incorporating molding sand patterns or shell cores. Ensuring uniform wall thickness throughout the casting is vital, which places high demands on the precision of core assembly. Any deviations in thickness can compromise the integrity and performance of the Heat Exchanger Parts.

Grain refinement, modification, and density index are critical parameters that must be meticulously controlled during the melting process. These factors influence the microstructure and tightness of the cast parts, as well as their chemical and mechanical properties. Achieving the correct balance ensures that the Heat Exchanger Parts meet the stringent requirements for durability and performance.

Once the casting process is complete, the parts undergo rigorous testing to ensure their integrity. A 100% leak test is mandatory, typically performed using air pressure or hydraulic pressure to detect any potential leaks. This step is crucial, as even minor leaks can lead to significant issues in the application of the heat exchangers.

The complexity of Heat Exchanger Parts extends beyond the casting process. These parts often need to withstand extreme temperatures and pressures, necessitating the use of high-quality materials and advanced manufacturing techniques. The precision in the casting and testing processes ensures that the parts can perform reliably under these demanding conditions.

In conclusion, the manufacturing of Heat Exchanger Parts is a highly specialized process that requires a deep understanding of materials science and engineering principles. From the initial core making to the final leak testing, each step must be executed with precision to produce parts that meet the rigorous standards required for their use in various industrial applications. The complexity and critical nature of these components underscore the importance of expertise and meticulous attention to detail in their production.