- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

wall hung condensing boiler heat exchanger 18-70kw

2022-04-20

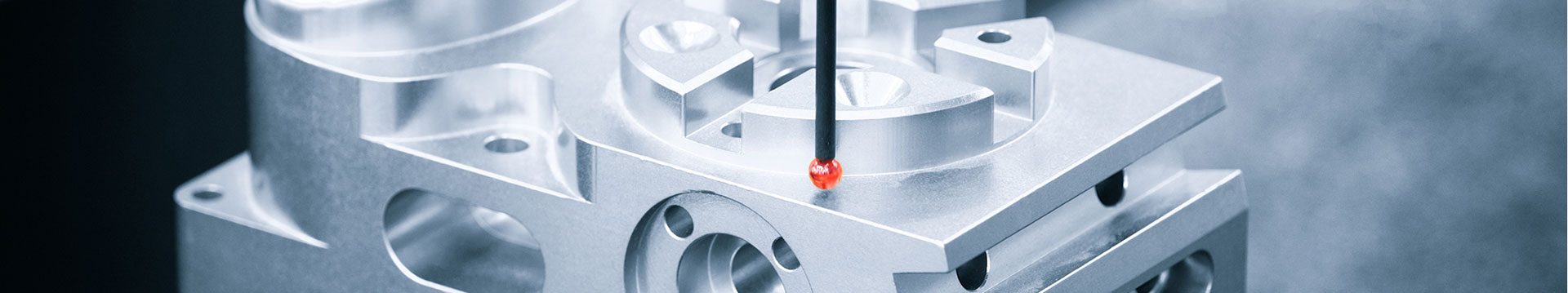

Aluminium casting domestic Condensing Heat Exchanger, is the main body component of the Condensing Boiler, the casting structure is complex and difficult to cast and mainly consists of pins and water channels. The core making uses different mesh size of sand to find the right balance in strength and gas release to avoid shrinkage or core breakage. Multiple combinations of cold and hot core assemblies with moulding sand patterns or shell cores. Casting wall thickness requires equalization therefore the precision of core assembly is highly demanding. Grain refinement, modification and density index need to be accurately controlled during melting to ensure that the tightness, structure, as well as the chemical and mechanical properties all meet the required ranges. Subsequently the process requires a 100% leak test, usually with air pressure or an hydraulic pressure test carried out by the foundry.

Condensing Heat Exchangers as used in condensing natural gas boilers transfer the heat onto the pins from which this heat is transferred to the water channel to heat up the water. The pins function is to absorb the heat from the down spiraling generated gas and to transfer this heat onto the water channel that runs from the bottom upwards in the Heat Exchanger. This heat exchange function generates low emissions and low exhaust temperatures into the atmosphere while heating the backwater temperature and recycles all available heat so that the heat efficiency can reach 108%. This results in an energy-saving and environmental protection, high-efficiency muted product. The saving of gas and reduction of fumes and heat into the atmosphere performs far better than from a non-condensing boiler. The Furesoro series is applicable to heating and hot water supply for a home, and is a new eco-friendly and energy-saving product promoted by various governments to replace non-condensing, coal, oil and electric water boilers.

Condensing Heat Exchangers as used in condensing natural gas boilers transfer the heat onto the pins from which this heat is transferred to the water channel to heat up the water. The pins function is to absorb the heat from the down spiraling generated gas and to transfer this heat onto the water channel that runs from the bottom upwards in the Heat Exchanger. This heat exchange function generates low emissions and low exhaust temperatures into the atmosphere while heating the backwater temperature and recycles all available heat so that the heat efficiency can reach 108%. This results in an energy-saving and environmental protection, high-efficiency muted product. The saving of gas and reduction of fumes and heat into the atmosphere performs far better than from a non-condensing boiler. The Furesoro series is applicable to heating and hot water supply for a home, and is a new eco-friendly and energy-saving product promoted by various governments to replace non-condensing, coal, oil and electric water boilers.