- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Igniting the fire of innovation and driving innovation in thermal energy management

2023-12-26

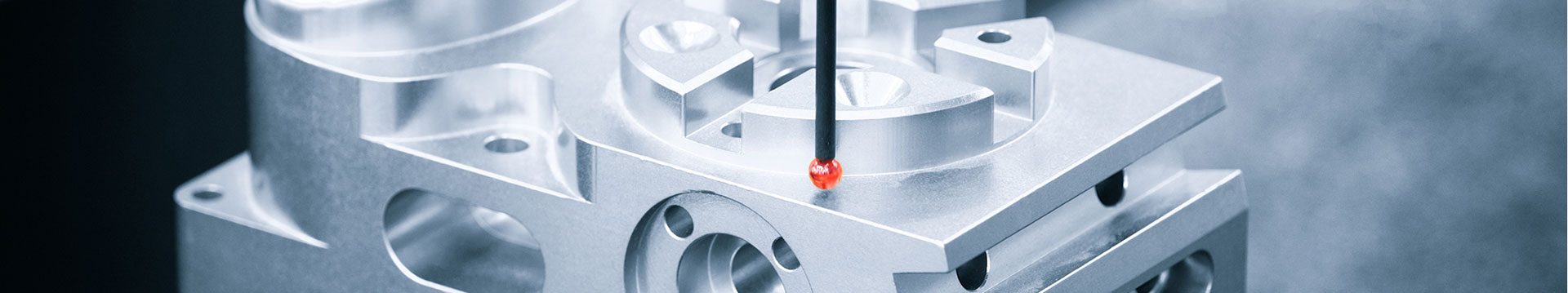

In the industrial sector, heat exchanger components are becoming a key force driving innovation in thermal energy management. Through continuous improvements in component design, materials and technology, heat exchanger systems are becoming more efficient and reliable, providing excellent thermal energy management solutions for various industries.

Key development trends in heat exchanger components:

Material innovation: The introduction of advanced materials such as highly corrosion-resistant alloys and high thermal conductivity composite materials makes heat exchanger components more weather-resistant and improves overall heat transfer efficiency.

Microchannel Technology: The increasing adoption of microchannel heat exchangers, whose small hydraulic diameter increases heat transfer rates, enables lightweight components and maximizes efficiency.

Intelligent sensing and control: Heat exchanger components integrate intelligent sensors and control systems to optimize thermal performance in real time. This enables the system to adapt adaptively to different operating conditions, ensuring energy efficiency and system reliability.

Improvement of surface coating: Apply advanced coating to the surface of the heat exchanger to increase the heat transfer rate, reduce fouling, and extend the service life of parts. Nanotechnology-based coatings are highly prized for their superior thermal properties.

Industry Outlook:

Continuous innovation in heat exchanger components is shaping a future in which thermal management solutions are not only more efficient, but also more environmentally friendly. As industries pursue sustainability, the integration of innovative materials and technologies will continue to drive progress.

Cross-industry applications:

Energy sector: Heat exchangers play a key role in power generation, and the latest component innovations improve the efficiency of conventional and renewable energy systems.

Automotive Industry: Improved heat exchanger components increase the efficiency of automotive cooling systems, helping to improve fuel efficiency and reduce emissions.

Chemical Processing: Highly corrosion-resistant materials and advanced coatings are particularly important for heat exchanger components in the harsh environments found in the chemical industry.

HVAC systems: Microchannel heat exchangers and intelligent control systems are used in HVAC systems to optimize energy consumption in heating, ventilation and air conditioning.

in conclusion:

The continued evolution of heat exchanger components reflects a commitment to advancing thermal engineering solutions across industries. As technological innovation continues to introduce new ones, the efficiency, reliability and environmental sustainability of heat exchangers will continue to increase to meet the growing needs of modern industrial processes.