- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

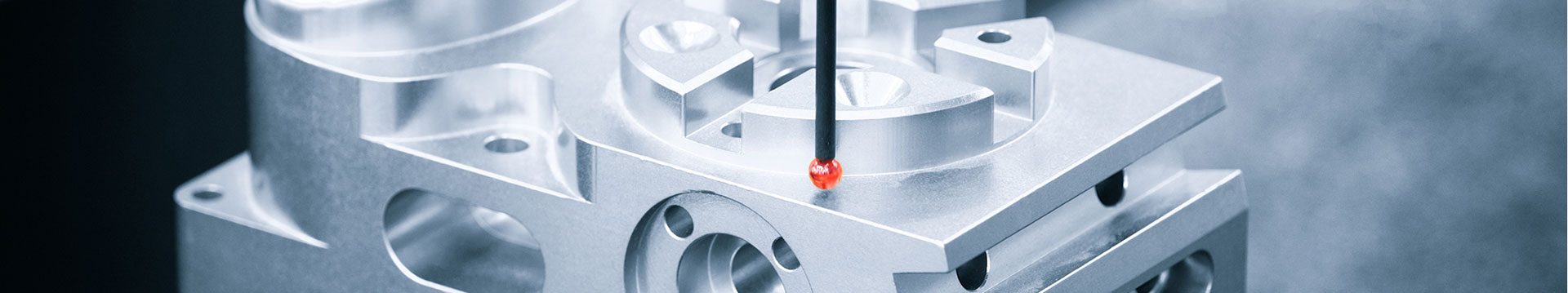

High precision machining-Temperature-controlled Machine Center

2024-05-27

HEC Machinery(JJ FOUNDRY) has set up Temperature-controlled Machine Center with a new gantry machining centre + thermostatic control room, mainly for controlling the coaxiality of deep holes in gearboxes, which can be achieved with its tiny tolerance accuracy. Machining deep hole can be controlled to less than 0.04mm.

-The constant temperature environment ensures more precise and stable temperature control during casting, reducing changes in material properties and casting defects due to temperature variations.

-Helps to reduce stress and cracks within the casting and improve the overall strength and durability of the casting.

-The ability of Temperature-controlled Machine Center to maintain a constant temperature environment is critical for deep hole machining. This is because temperature fluctuations can directly affect the cutting performance and machining accuracy of the material. By precisely controlling the temperature, machining errors due to thermal expansion and contraction can be reduced.

-Temperature-controlled Machine Center can reduce tool wear and damage. In a constant temperature environment, the cutting performance of the tool is more stable, reducing the thermal crack and wear of the tool due to temperature fluctuations, and deep hole machining can achieve higher precision control.

-Temperature-controlled Machine Center can improve the surface quality of deep hole machining. Under a stable temperature environment, the cutting process is smoother, reducing cutting force and vibration, which in turn reduces surface roughness and ripple.

Temperature-controlled Machine Center has significant help and advantages for HEC Machinery in improving product quality, increasing productivity, saving energy and resources, improving working environment, supporting technological innovation and R&D as well as achieving environmental protection and sustainable development.