- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

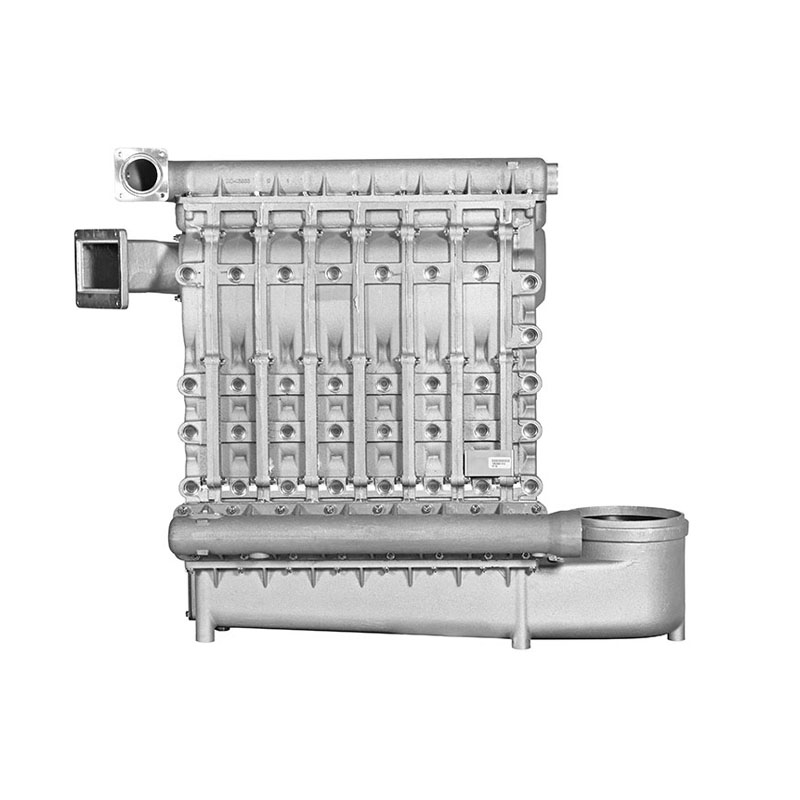

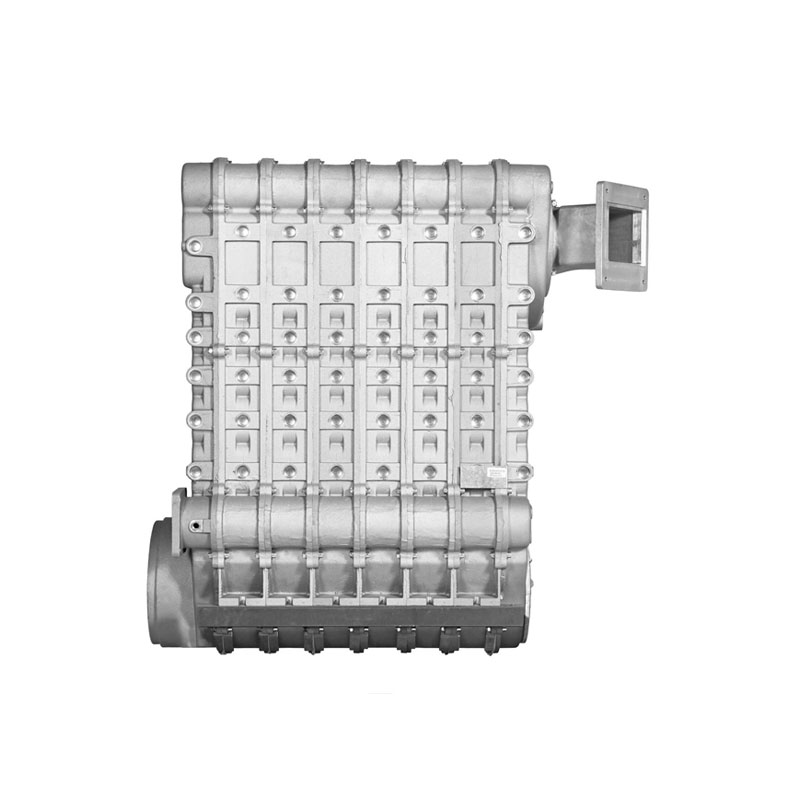

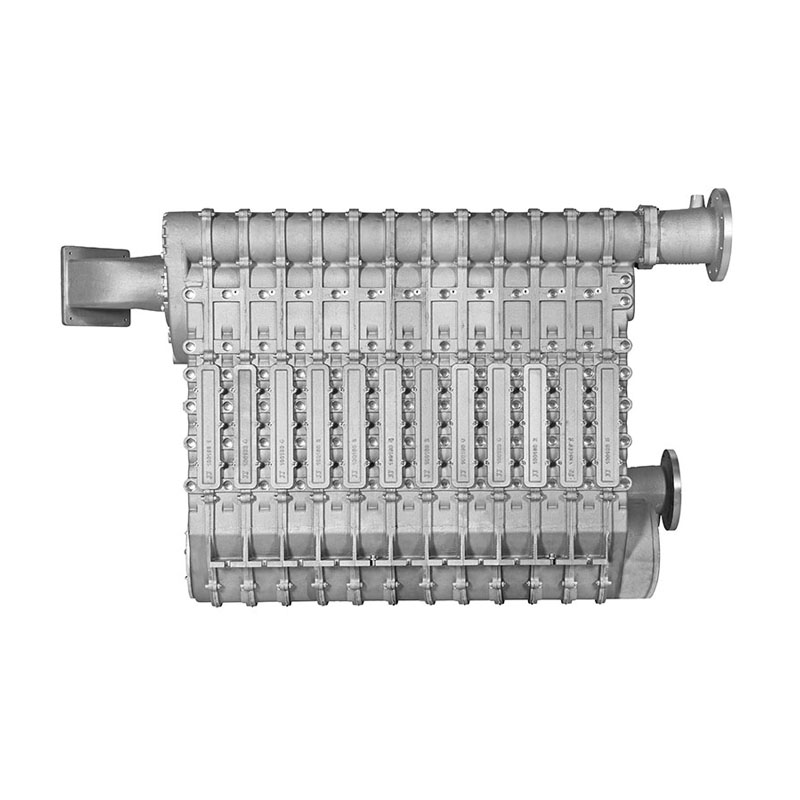

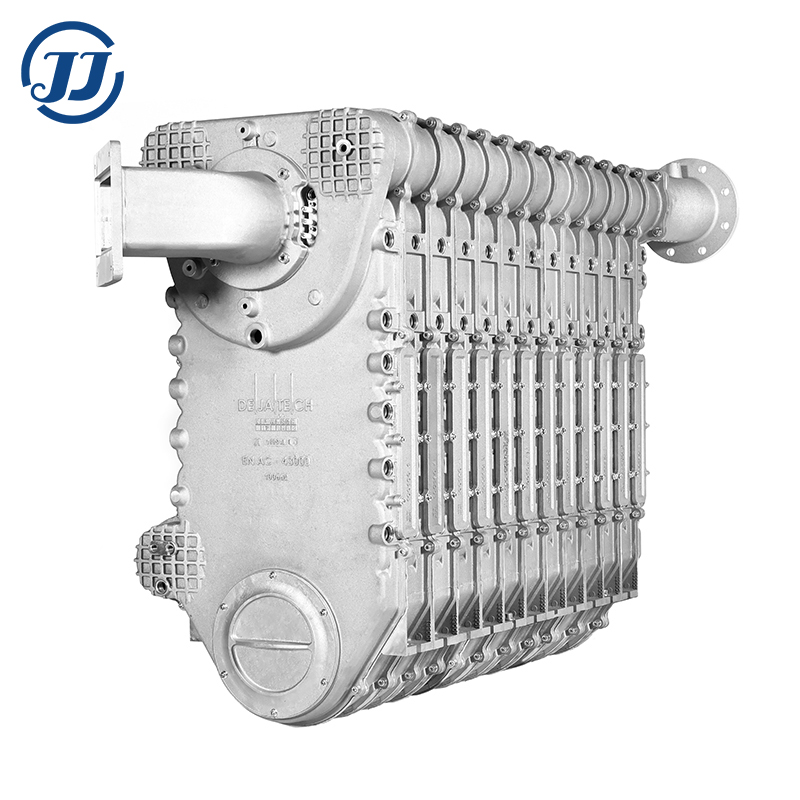

Condensing Heat Exchanger

Condensing Heat Exchanger

Condensing Heat Exchanger as used in condensing natural gas boilers transfer the heat onto the pins from which this heat is transferred to the water channel to heat up the water. The pins function is to absorb the heat from the down spiraling generated gas and to transfer this heat onto the water channel that runs from the bottom upwards in the Heat Exchanger. This heat exchange function generates low emissions and low exhaust temperatures into the atmosphere while heating the backwater temperature and recycles all available heat so that the heat efficiency can reach 108%. This results in an energy-saving and environmental protection, high-efficiency muted product. The saving of gas and reduction of fumes and heat into the atmosphere performs far better than from a non-condensing boiler.

Our condensing heat exchanger is applicable to heating and hot water supply for home or large area, and is a new eco-friendly and energy-saving product promoted by various governments to replace non-condensing, coal, oil and electric water boilers.

We have ISO 9001:2015, ISO 14001:2004, KIWA and ASME certificates for both condensing heat exchanger and foundry. We provide one-stop purchasing from optimized of design, to tooling-, casting-, machining-, assembly-, coating-, etc and offer all kind of casting method such as sand casting, shell core, gravity casting and die-casting (high and low pressure).

Heat Exchanger Parts

Heat Exchanger Parts

The material of heat exchanger parts is EN1706/AC43000. We have various types of heat exchanger parts to match 18kw-2800kw condensing boilers.

As for heat exchanger parts, the casting structure is complex and difficult to cast and mainly consists of pins and water channels. The core making uses different mesh size of sand to find the right balance in strength and gas release to avoid shrinkage or core breakage. Multiple combinations of cold and hot core assemblies with moulding sand patterns or shell cores. Casting wall thickness requires equalization therefore the precision of core assembly is highly demanding. Grain refinement, modification and density index need to be accurately controlled during melting to ensure that the tightness, structure, as well as the chemical and mechanical properties all meet the required ranges. Subsequently the process requires a 100% leak test, usually with air pressure or an hydraulic pressure test carried out by the foundry.

Certificates:ISO 9001:2015, ISO 14001:2004 certified and ASME certification

We have established long-term and stable cooperative relations with many of the world's top 500 enterprises and set up a sales office, R&D, storage warehouse, assembly line and laboratory in Belfeld, the Netherlands, our Dutch and Chinese technical engineers and casting/machining specialists can provide services beyond your expectations, giving advice on the feasibility and cast-ability of the design so as to help customers to save time and cost, giving you the necessary support on a successful launch of your project.

Motorcycle Parts

Motorcycle Parts

After years of accumulation of experience in die-casting process, the Motorcycle Parts manufactured by us is beautiful in appearance, sturdy and durable.We can also open the mold according to your drawings. Our mold can be molded at one time, with high product accuracy and less bubbles. If you have any questions, welcome consult.

We have ISO 9001:2015, ISO 14001:2004 and ASME certificates for both foundry and assembly. We provide one-stop purchasing from optimized of design, to tooling-, casting-, machining-, assembly-, coating-, etc. Next to motorcycle parts casting we also have the possibility to machine the castings, perform T5/T6 treatment, coating (wet/powder/anodising/chromate) and assembly of the components in our factories.

Hybrid Boiler

Hybrid Boiler

hybrid boiler heat pump system combines a boiler and a heat pump, in which the heat pump provides the primary heat supply whereas the boiler kicks in once the heat pump is not sufficient. what makes a hybrid heat pump solution unique is the simple integration of the piping and the software that ensures an improved efficiency and optimal co2-reduction. it saves up to 50% on gas consumption.

Integrated heat pump and condensing central heating boiler with capacities between 168 - 600 kw. Flexible up to a maximum of 4 LG heat pump units 32/64/96/128 kW.

We have established long-term and stable cooperative relations with many of the world's top 500 enterprises and set up a sales office, R&D, storage warehouse, assembly line and laboratory in Belfeld, the Netherlands, our Dutch and Chinese technical engineers and casting/machining specialists can provide services beyond your expectations, giving advice on the feasibility and cast-ability of the design so as to help customers to save time and cost, giving you the necessary support on a successful launch of your project.

Featured Products

About Us

-

Overseas Warehouse

(Dutch)

Overseas Warehouse

(Dutch)Keep a certain amount of stock,with our overseas warehouse can do just-in-time deliveries.

View Details -

Extensive Casting

Experience

Extensive Casting

ExperienceHave more than 30 years of casting experience; Equipped with domestic and foreign professionals, technical, R&D and multilingual sales teams, focusing on the development of aluminum castings with complex design structure.

View Details -

Complete Supporting

Services

Complete Supporting

ServicesFrom optimizing design, mold opening, casting, machining, assembly, surface treatment, packaging, warehousing, and transportation for customers, we provide one-stop OEM/ODM services.

View Details -

Strict Inspection

Standards

Strict Inspection

StandardsHave a complete and traceable raw material, production process and finished product inspection; Controllable PPM ratio; A system to quickly resolve customer complaints.

View Details -

Various casting

methods and equipment

Various casting

methods and equipmentCan provide various casting methods such as sand-,shell core-, gravity-, high and low pressure die casting; Equipped with 100+ CNC processing centers; 200+ core-making equipment.

View Details

New Products

News

New Equipment-SUGINO High Pressure Water Jet Deburring

JJ Foundry has introduced SUGINO High Pressure Water Jet Deburring to provide strong technical support for improving product quality and production efficiency.

High precision machining-Temperature-controlled Machine Center

JJ FOUNDRY new Inspection Centre

What is condensing heat exchanger?

Sand casting by JJ Foundry

Introduce what is sand casting and the advantage of JJ casting